We’re a data-driven asset integrity management firm, using smart tech and innovation to enhance energy sector assets’ safety and profitability. Just as we help companies build growth foundations, we empower our team’s growth.

Revolutionizing the Energy Sector with

Cognitive Solutions

We’re a data-driven asset integrity management firm, using smart tech and innovation to enhance energy sector assets’ safety and profitability. Just as we help companies build growth foundations, we empower our team’s growth.

Revolutionizing the Energy Sector with

Cognitive Solutions

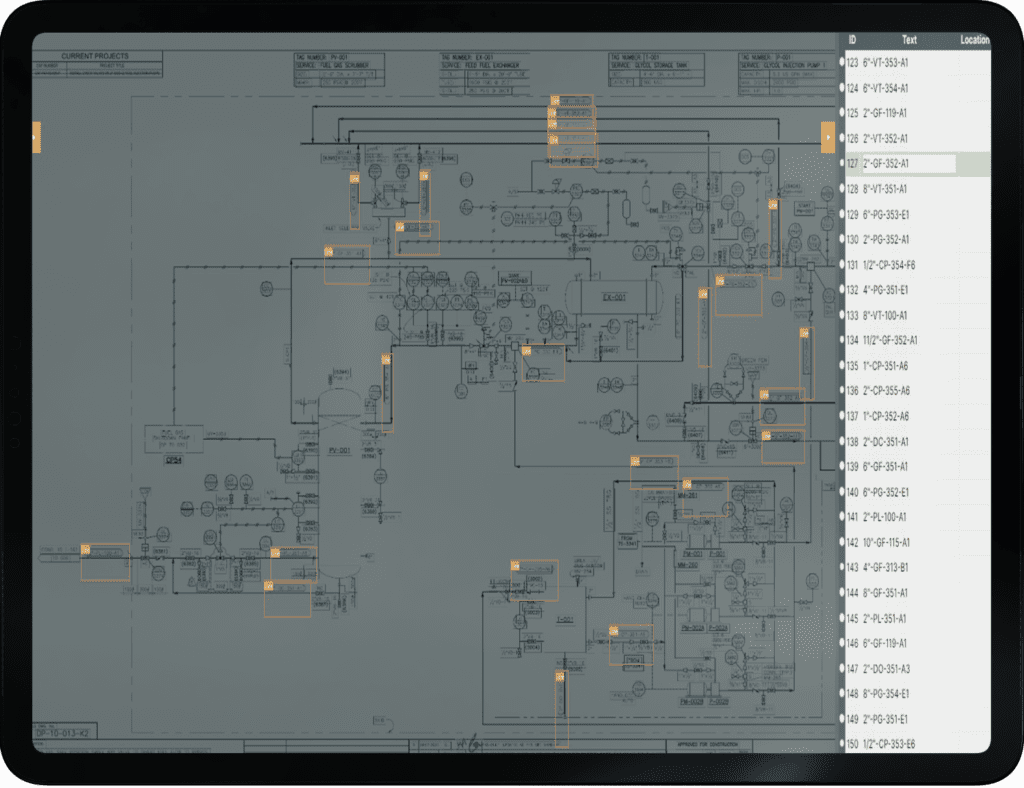

Connect AI is an advanced software solution that utilizes Artificial Intelligence (AI) and Machine Learning (ML) to improve asset integrity management in the energy sector. It is designed to automatically extract, label, and correlate information from engineering diagrams and inspection reports. The software uses a combination of NLP, OCR, and computer vision to process large volumes of unstructured and decentralized data and convert it into structured, centralized, and high-quality information that can be used for better decision making and digitization of assets. The aim of Connect AI is to provide a comprehensive and interactive picture of the integrity of an asset, enabling engineers and asset managers to carry out quantitative risk assessments and manage risks more effectively.

Connect AI

Connect AI is an advanced software solution that utilizes Artificial Intelligence (AI) and Machine Learning (ML) to improve asset integrity management in the energy sector. It is designed to automatically extract, label, and correlate information from engineering diagrams and inspection reports. The software uses a combination of NLP, OCR, and computer vision to process large volumes of unstructured and decentralized data and convert it into structured, centralized, and high-quality information that can be used for better decision making and digitization of assets. The aim of Connect AI is to provide a comprehensive and interactive picture of the integrity of an asset, enabling engineers and asset managers to carry out quantitative risk assessments and manage risks more effectively.

Connect AI

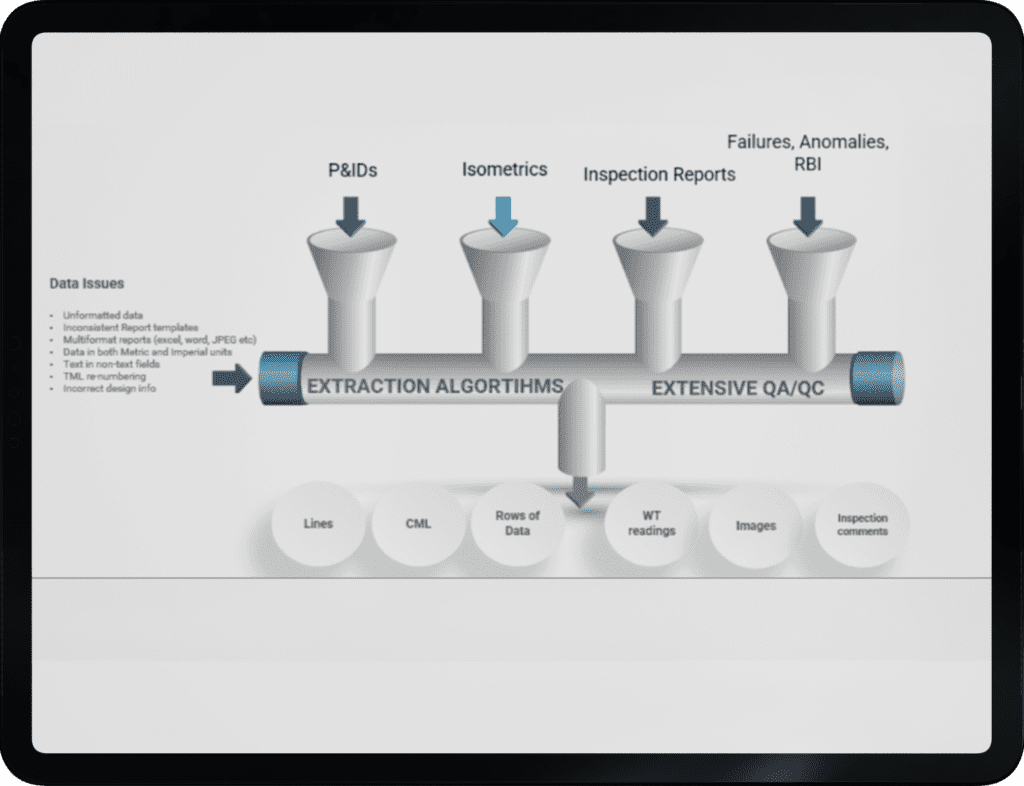

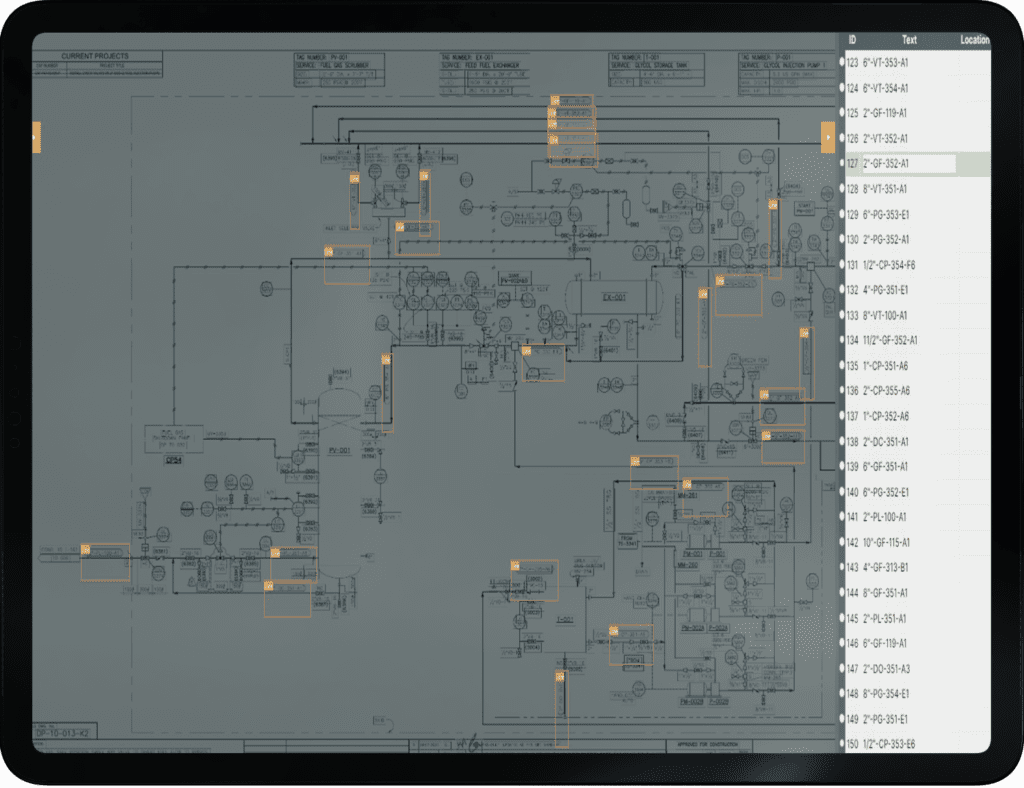

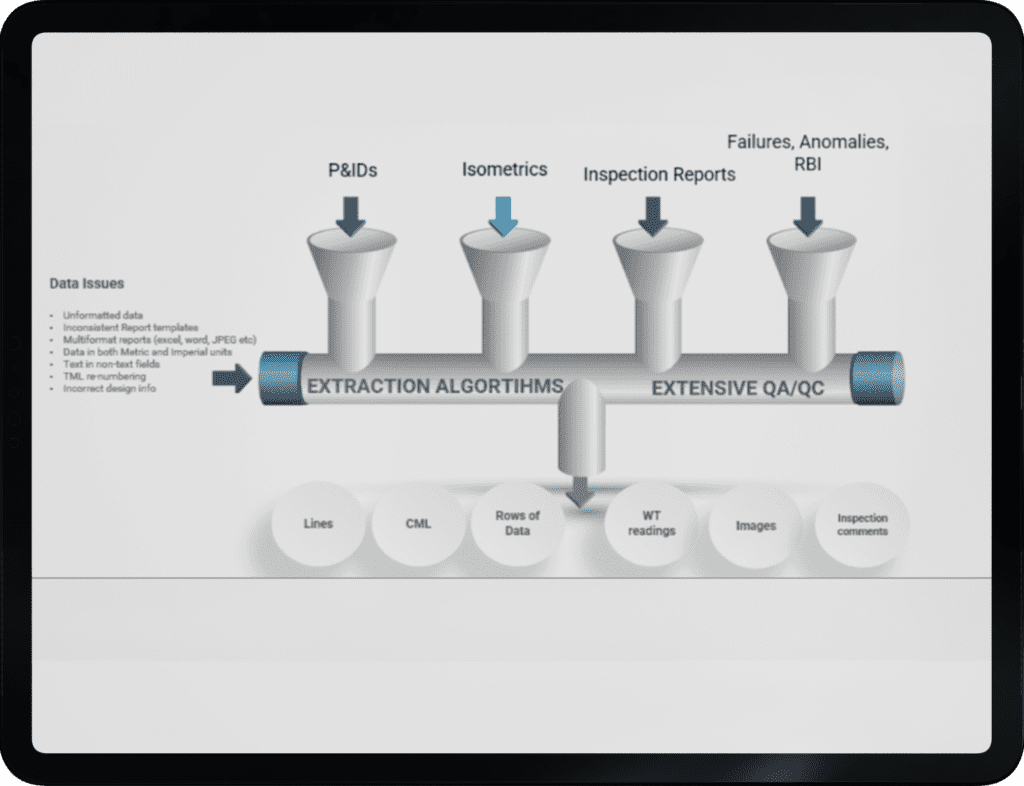

Extract solves the problem of high volumes of multiformat, poor quality, unstructured and decentralized data gathered during inspection and maintenance activities by converting into structured, centralized and high-quality information which then can be used for better decision making and digitization of assets.

Any industry or asset which requires legacy data to be digitized and turned into sustainable business value.

It uses a combination of Machine learning, NLP, OCR and Computer vision.

Extract

Automatically extracts, labels and correlates information from engineering diagrams and inspection reports.

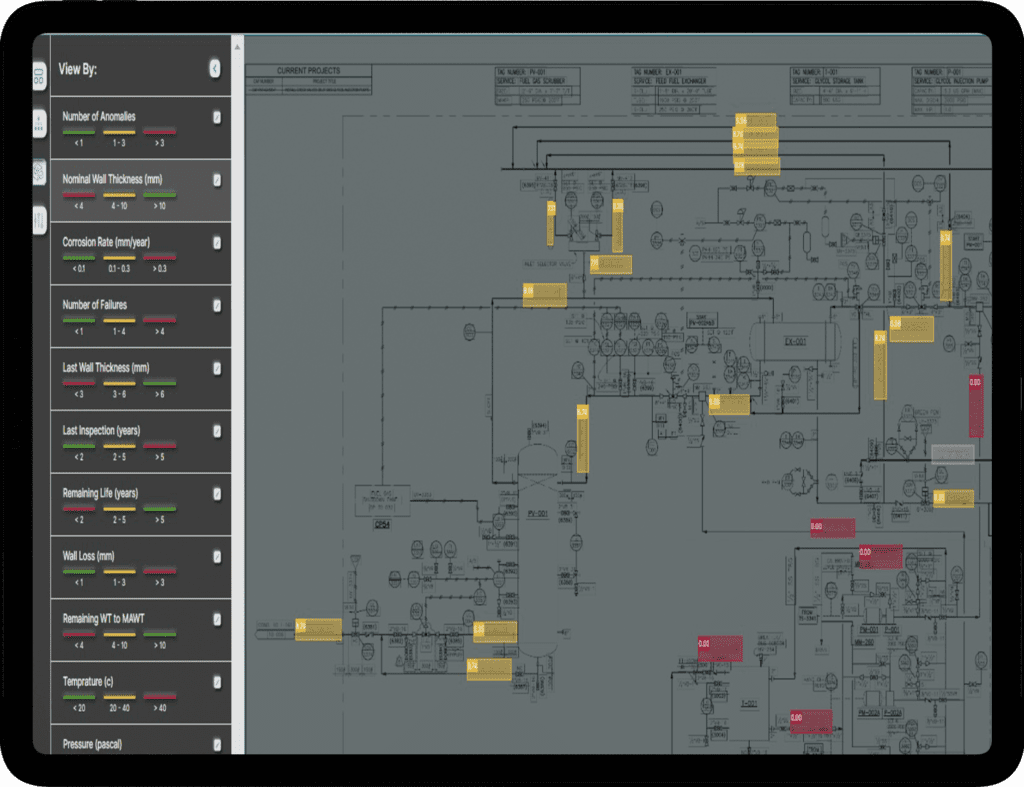

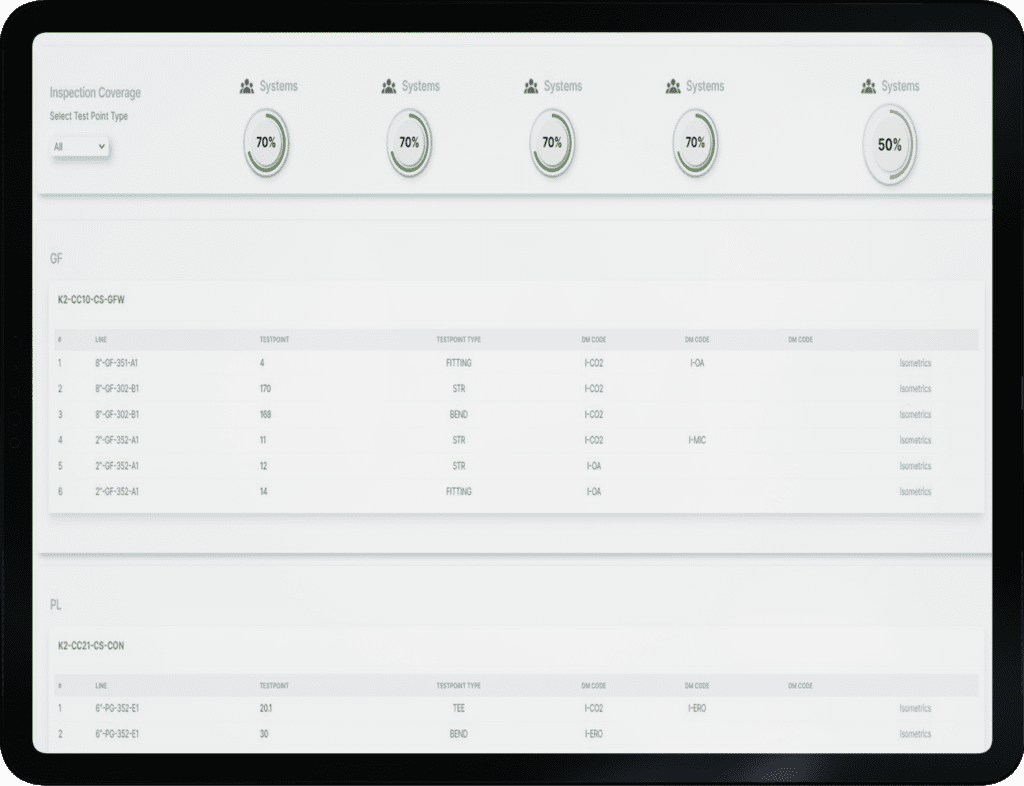

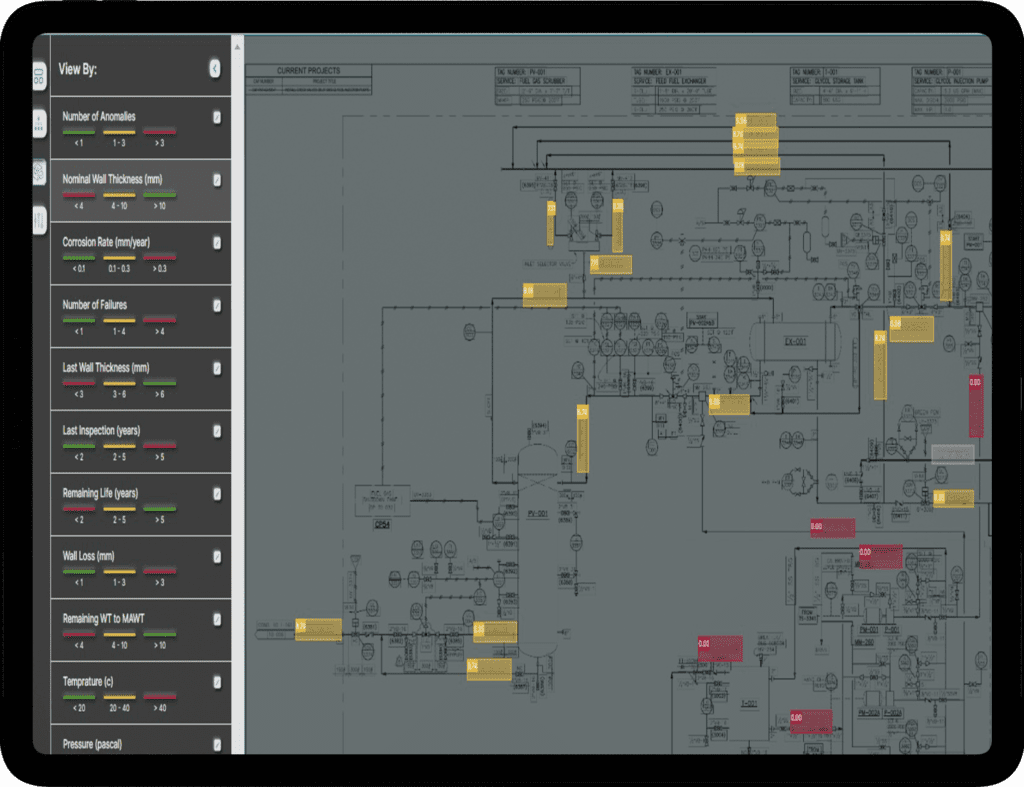

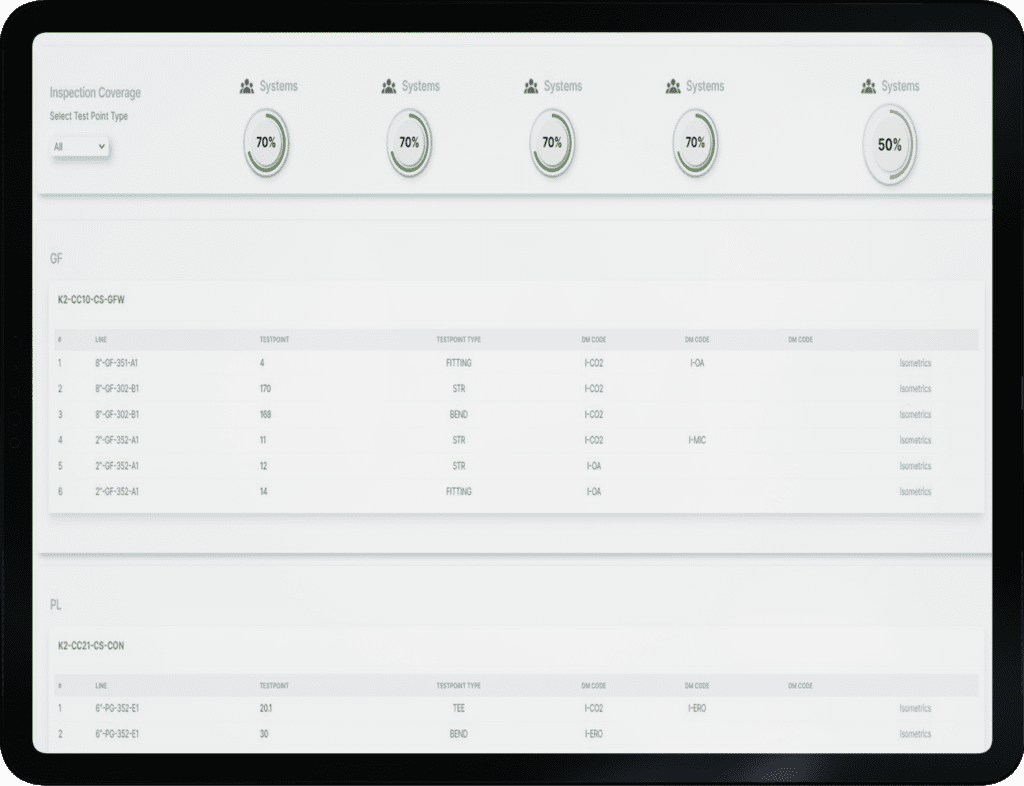

Interact

A Visual data management and analytics tool which provides a ‘full and interactive picture’ of the integrity and helps engineers carry out quantitative risk assessments.

Why does it do it?

It solves the issue of lack of visibility of the elements that actually contribute to operational risk and have no defined means of managing them.

A strong data management and data analytics platform like Visionnect provides the means of viewing all the risk and their associations on a single platform.

Engineers and Asset Managers whose daily activities involve risk and safety management.

It uses machine learning and modern Web programming.

Why does it do it?

It helps to reduce the over-inspection and resources allocation thus assisting in budget optimization, better profitability and preventing inspection backlogs KPIs.

Planners, Inspectors and Engineers who are involved in day to day inspection, risk and anomaly management.

It uses AI assisted work scope management tools.

Enact

A resource planning and work scope management tool which helps in targeted inspection for optimized inspection and threats management.

React

A Visual data management and analytics tool which provides a ‘full and interactive picture’ of the integrity and helps engineers carry out quantitative risk assessments.

Why does it do it?

It uses real-time data to monitor IOW to identify hard to detect issues and change in data patterns which would not be possible to obtain from conventional approaches.

Engineers and Asset Managers who are involved in risk management.

It uses AI and Machine learning on data acquired from IoT sensors.

Discover an Array of Visionnect's Offerings

Connect AI

Data Driven RBI

Event Driven Inspection

Data Driven Integrity

Management

Data Driven Integrity

Management

Data Driven RBI

Event Driven Inspection

Robotic Process Automation

Leak Detection System

Event Driven Inspection

Data Driven Integrity

Management

Robotic Process Automation

Extract

Automatically extracts, labels and correlates information from engineering diagrams and inspection reports.

Extract solves the problem of high volumes of multiformat, poor quality, unstructured and decentralized data gathered during inspection and maintenance activities by converting into structured, centralized and high-quality information which then can be used for better decision making and digitization of assets.

Any industry or asset which requires legacy data to be digitized and turned into sustainable business value.

It uses a combination of Machine learning, NLP, OCR and Computer vision.

Interact

A Visual data management and analytics tool which provides a ‘full and interactive picture’ of the integrity and helps engineers carry out quantitative risk assessments.

Why does it do it?

It solves the issue of lack of visibility of the elements that actually contribute to operational risk and have no defined means of managing them.

A strong data management and data analytics platform like Visionnect provides the means of viewing all the risk and their associations on a single platform.

Engineers and Asset Managers whose daily activities involve risk and safety management.

It uses machine learning and modern Web programming.

Enact

A resource planning and work scope management tool which helps in targeted inspection for optimized inspection and threats management.

Why does it do it?

It helps to reduce the over-inspection and resources allocation thus assisting in budget optimization, better profitability and preventing inspection backlogs KPIs.

Planners, Inspectors and Engineers who are involved in day to day inspection, risk and anomaly management.

It uses AI assisted work scope management tools.

React

A Visual data management and analytics tool which provides a ‘full and interactive picture’ of the integrity and helps engineers carry out quantitative risk assessments.

Why does it do it?

It uses real-time data to monitor IOW to identify hard to detect issues and change in data patterns which would not be possible to obtain from conventional approaches.

Engineers and Asset Managers who are involved in risk management.

It uses AI and Machine learning on data acquired from IoT sensors.

Connect AI

Data Driven RBI

Event Driven Inspection

Data Driven Integrity management

Robotic Process Automation